Rusty McNeil

Well-Known Member

I just spoke with Dyna on this lap top programmable unit.

The old dip switch programmable unit is completely discontinued.

The new lap top programmable unit has replaced it, and it's more than just programmable, it has all the features you'd expect on a modern unit.....

It still carries the same part number, D3K7-6 for the 90-07 bikes, and is the same price of $292.00

Very importantly, they are also building this unit for the early bikes, 85-89 as well, part number D3K7-7

So don't waste your time looking for one of those early long discontinued units.

He did say they are building them as fast as they can and supply is backlogged at times...

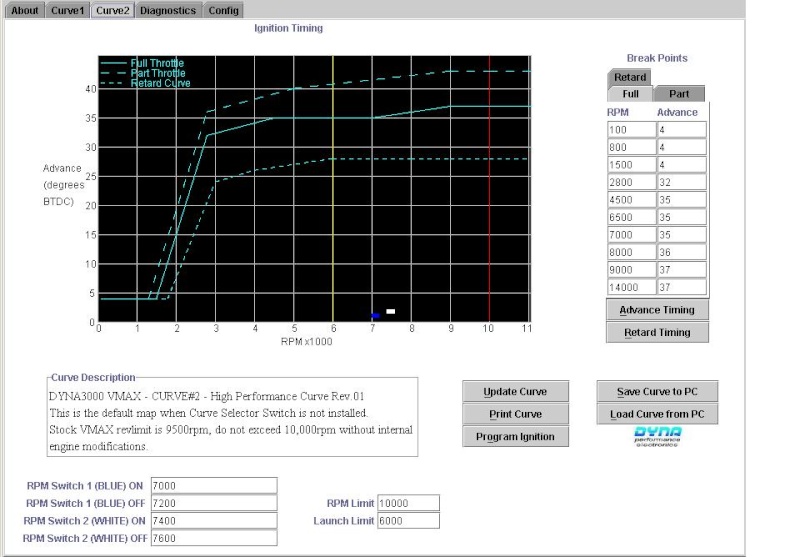

The tech guy says that it has two pre-built maps, which can be selected by switch externally between the two maps, and these maps can be modified individually between full throttle, part throttle, and retard curve for each of the two maps. The full throttle/part throttle selection is dictated by what the map sensor sees.

Each map has the advance curves for full throttle, part throttle, and retard/no throttle

It also has an external retard input, which activates the retard portion of the map your in, which also has three curves for full, part, and retard/no throttle.

This would be ideal for those of us with Widebands that wanted to use a programmable output on the wideband to drive retard, as an example;

Lets say I set my wideband to drive an output if RPM is over 7000 and a/f is leaner than 15:1, then it could be used to drive retard curve into operation to fight unintended detonation

Also has two rpm window switch outputs...with individually selectable on/off rpm points for each, whci could be used shift lights, nitrous activation etc...

Launch control....when clutch is pulled in it liimits rpm to programmable value...let the clutch out and the limit is removed.

Data Logging.........

And some other stuff I probably missed...

The installation instructions on the website havent been updated, still referencing the old unit, but if you go to software downloads for Dyna 3000, select for carbed bikes, unzip and install you'll eventually get to some PDF files explaining the features and an overview of the software....You can open the software and play a little but to do much very much it needs to be connected to the unit

I"ve attached a copy of the PDF for our bike...but if you download the software package there is more available...

Would anyone guess that I'm on three weeks vacation and getting bored?

The old dip switch programmable unit is completely discontinued.

The new lap top programmable unit has replaced it, and it's more than just programmable, it has all the features you'd expect on a modern unit.....

It still carries the same part number, D3K7-6 for the 90-07 bikes, and is the same price of $292.00

Very importantly, they are also building this unit for the early bikes, 85-89 as well, part number D3K7-7

So don't waste your time looking for one of those early long discontinued units.

He did say they are building them as fast as they can and supply is backlogged at times...

The tech guy says that it has two pre-built maps, which can be selected by switch externally between the two maps, and these maps can be modified individually between full throttle, part throttle, and retard curve for each of the two maps. The full throttle/part throttle selection is dictated by what the map sensor sees.

Each map has the advance curves for full throttle, part throttle, and retard/no throttle

It also has an external retard input, which activates the retard portion of the map your in, which also has three curves for full, part, and retard/no throttle.

This would be ideal for those of us with Widebands that wanted to use a programmable output on the wideband to drive retard, as an example;

Lets say I set my wideband to drive an output if RPM is over 7000 and a/f is leaner than 15:1, then it could be used to drive retard curve into operation to fight unintended detonation

Also has two rpm window switch outputs...with individually selectable on/off rpm points for each, whci could be used shift lights, nitrous activation etc...

Launch control....when clutch is pulled in it liimits rpm to programmable value...let the clutch out and the limit is removed.

Data Logging.........

And some other stuff I probably missed...

The installation instructions on the website havent been updated, still referencing the old unit, but if you go to software downloads for Dyna 3000, select for carbed bikes, unzip and install you'll eventually get to some PDF files explaining the features and an overview of the software....You can open the software and play a little but to do much very much it needs to be connected to the unit

I"ve attached a copy of the PDF for our bike...but if you download the software package there is more available...

Would anyone guess that I'm on three weeks vacation and getting bored?