Zenuwlijer

Well-Known Member

Hi folks,

It's winter, so I've got the time to learn stuff. Grabbed the Haynes manual in combination with the howto from @naughtyG and got started.

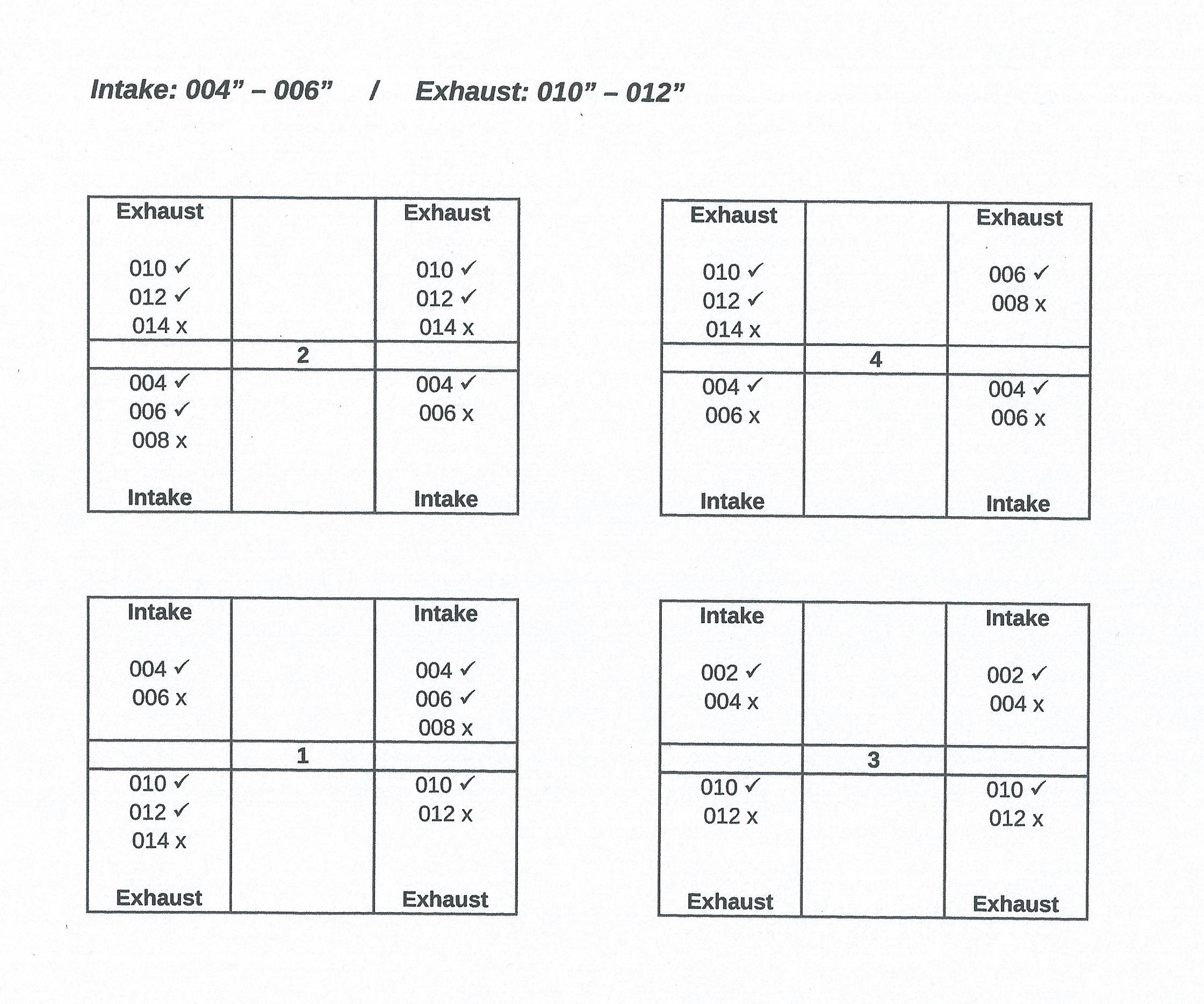

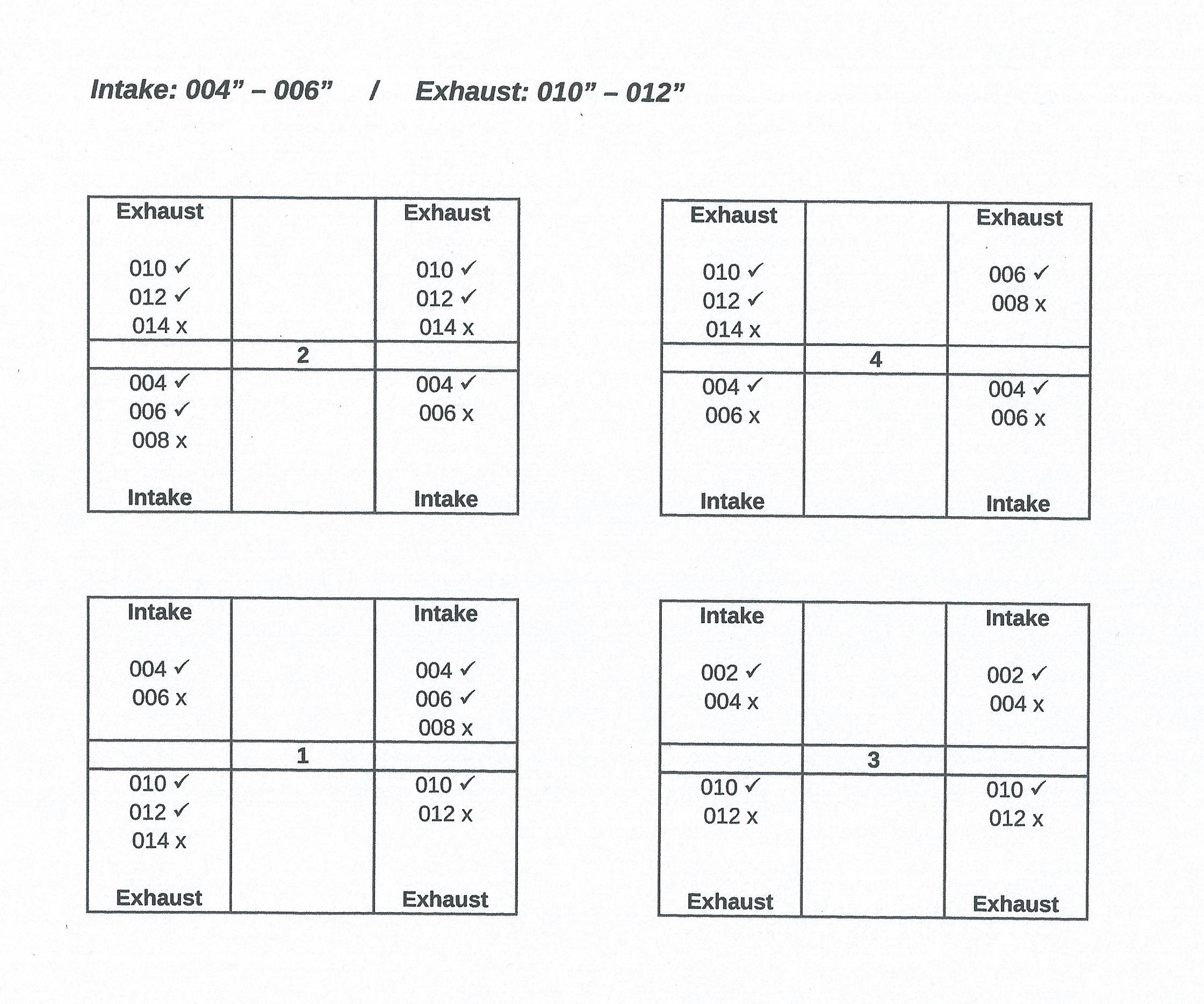

I've measured the valve clearances and most of them are off spec. Some are too loose, some are too tight.

The bike is running well and without problems as far as I can tell. Before I take all the shims out, I could use some guidance as in how to move forward.

It's winter, so I've got the time to learn stuff. Grabbed the Haynes manual in combination with the howto from @naughtyG and got started.

I've measured the valve clearances and most of them are off spec. Some are too loose, some are too tight.

The bike is running well and without problems as far as I can tell. Before I take all the shims out, I could use some guidance as in how to move forward.