That's funny-I tossed my overpriced iridiums a week after i bought them.

If you tossed them after a week you don't understand what they are intended for.

The value in iridium's (and platinum's or any rare earth/noble metals) is the wear characteristics compared to more conventional plugs. If you're expecting anything besides longevity in using them (IE: hp, mileage, smoother engine, etc) you're going to be disappointed. Their intended use is to hold their gap more precisely over longer periods. They are far less subject to the spark erosion normal plugs experience. That's why OEMs use them and why they have the extended change intervals.

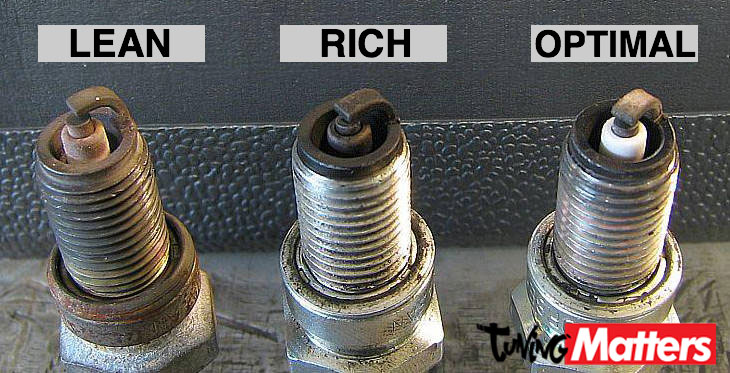

If you installed them and had troubles (ie: carbon fouling, missing, ET loss, etc) you have other problems than the spark plugs. Assuming you installed the correct plug for the application that is.

It is possible to see an mpg improvement or smoother engine, but it's an average over the total lifespan of the plug because of it's consistency not because it has some secret performance advantage over conventional plugs. The lifespan of iridium's is in the 80-100,000 mile area, not over a couple tanks of fuel.

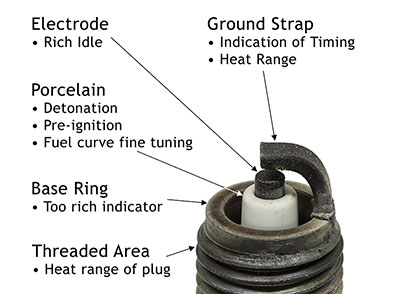

The side bonus is since the wear characteristics are superior, the points can be made sharp and small. This is important to spark plug action as spark jumps from the center electrode to the ground electrode from the sharpest point. In a conventional plug, it jumps from the edge of the center electrode where the sharp point is. It's also why it dances around that edge, every time a spark jumps it blows off a few molecules of metal making the next sharp point elsewhere on the edge. This is wear and why you chuck conventional plugs when the center electrode is worn over it's edge. It's also why the gap opens over time and you need to regap at intervals or just toss it. You could make a conventional looking spark plug with a complete iridium center electrode, but it's not needed due to the wear characteristics of the iridium and it would exponentially drive the cost up. That cost is also why only the very tip of that sharpened center electrode is iridium. It's just that good for wear in this application.

Rare earth metals don't experience the same wear so the spark is consistent, which makes for more consistent combustion over a longer period of time.

These are facts and not up for discussion. Arguing contrary only shows lack of knowledge of the science behind the product.

Some people have said they experienced better running by installing iridium's, but in those cases the plug is only covering deficiencies elsewhere in the ignition system or the conventional plugs were worn to a point where they should have already been replaced. I've had it happen myself: install iridium's, runs better. But I knew that wasn't the end of it, I chased it down and found corroded resistors in a couple of the spark plug caps which had raised the total resistance making the spark at the gap weaker. Changed the caps, then same running with iridium's or fresh conventional plugs.

Because the plug has sharp spark jump points, it's easier for a weak ignition to jump the spark. Or if their ignition system is indeed healthy, they're just experiencing the placebo effect: they're looking for a difference so they feel one.

Spark plugs don't need gimmicks like slots, grooves or whatever. That's all marketing hype to suck in the unknowing and grab your dollar. Spark plugs need a sharp consistent edge for spark to jump from and for it not to be blown away by the spark action (IE: wear). The rest is heat management and conductivity.

There is no "black magic", "secret process" or gov't plot to hide a "100 mpg spark plug" here, there's just good solid science. It's not subjective, it's black and white. You understand it or you don't. Plain and simple.

Now I'm done talking about it in this thread. This thread is about carb adjustments, not spark plugs.

Go start your own thread about spark plugs if you have an axe to grind.