QuarterHorse

Well-Known Member

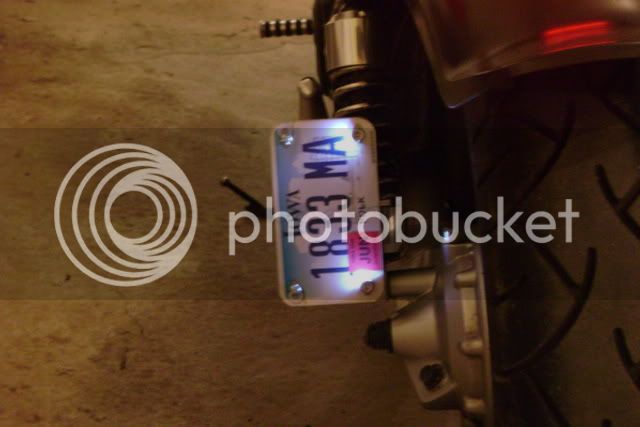

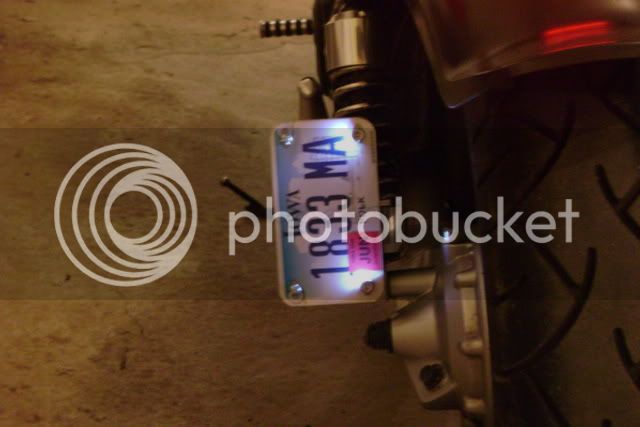

I have the tag lights on Mad Max. It took two trys for Custom Dynamics to get it right, as the first set they sent one LED was bad. They mailed out the warranty one Friday, I got it today, and got 'em installed. The only thing I don't like about 'em is that the studs are a little long on the back, and I don't have a steady enough hand to cut 'em down and not hit the wires inside 'em. Hiding the wires is also a pain in the butt.

They seem to work well, or well enough to keep po-po off my back about it.

They seem to work well, or well enough to keep po-po off my back about it.