How much it normally would pulse? Mine goes from none to full back and forth, is that normal?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The IGNITECH TCI thread

- Thread starter wildweasel_pt

- Start date

Help Support VMAX Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

alorio1

Well-Known Member

How much it normally would pulse? Mine goes from none to full back and forth, is that normal?

I personally think the restrictor is needed to keep the pulses at a minimum.

Traumahawk

Well-Known Member

Edited for content

Last edited:

That TPS bar went from 100% to 0% all the time I got it hooked up, I think the lowest voltage was 1.6xx and highest 4.6xx. I have now 0% - 2.1V and 100% - 4.34V The Max Is Alive Again!

I still got a little sneezing when slowly accelerating 2.nd gear and at 3.rd gear cruising with low rpms, but bike responses to throttle a lot better and it didn't sputter like it did with old settings. i think I'm goin to put 0% - 1.7V and

100% - 4.5V to get it even better. Thank you all for your help, I really appreciate :worthy:

I still got a little sneezing when slowly accelerating 2.nd gear and at 3.rd gear cruising with low rpms, but bike responses to throttle a lot better and it didn't sputter like it did with old settings. i think I'm goin to put 0% - 1.7V and

100% - 4.5V to get it even better. Thank you all for your help, I really appreciate :worthy:

dingy

Well-Known Member

Below is how to smooth out pulses, if you really want to.

Pictures are in random order, sorry.

I attached a 5 port connector I got at Auto Zone. one port to each sync nipple and 5th port to a small canister. I used 1 1/4" pvc pipe & 2 caps. After experimenting with several lengths of the canister, I found that shortest canister affected throttle lag caused by added air buffer in canister and also smoothed pules out greatly.

3rd picture, hose connection is below carbs.

Also picture of stock air restrictor and one that Auto Zone carries.

Last picture is of 1st try at canister, way to long, this caused a lag after throttle opened up for vacuum to catch up. Not a lot, but not good.

Gary

Pictures are in random order, sorry.

I attached a 5 port connector I got at Auto Zone. one port to each sync nipple and 5th port to a small canister. I used 1 1/4" pvc pipe & 2 caps. After experimenting with several lengths of the canister, I found that shortest canister affected throttle lag caused by added air buffer in canister and also smoothed pules out greatly.

3rd picture, hose connection is below carbs.

Also picture of stock air restrictor and one that Auto Zone carries.

Last picture is of 1st try at canister, way to long, this caused a lag after throttle opened up for vacuum to catch up. Not a lot, but not good.

Gary

Attachments

Traumahawk

Well-Known Member

So Gary....do you need to smooth out the pulses...IE will it affect the performance of the ignitech unit, or is it a personal preference thing?

dingy

Well-Known Member

So Gary....do you need to smooth out the pulses...IE will it affect the performance of the ignitech unit, or is it a personal preference thing?

It was an experiment due to seeing the pulsing through software. I haven't since 2 years ago.

If the TCI has smoothing software code it should average pulses. This may be one advantage that the IAP setting has. When Ignitech upgraded software about 2 years ago, IAP setting was intended for MAP applications.

Gary

Traumahawk

Well-Known Member

Edited for content

Last edited:

thor_eyerdhal

Well-Known Member

Could you try the performance curve or the new programmable dyna?

With raised advance beyond max torque RPM, it should add some ponies...

With raised advance beyond max torque RPM, it should add some ponies...

Traumahawk

Well-Known Member

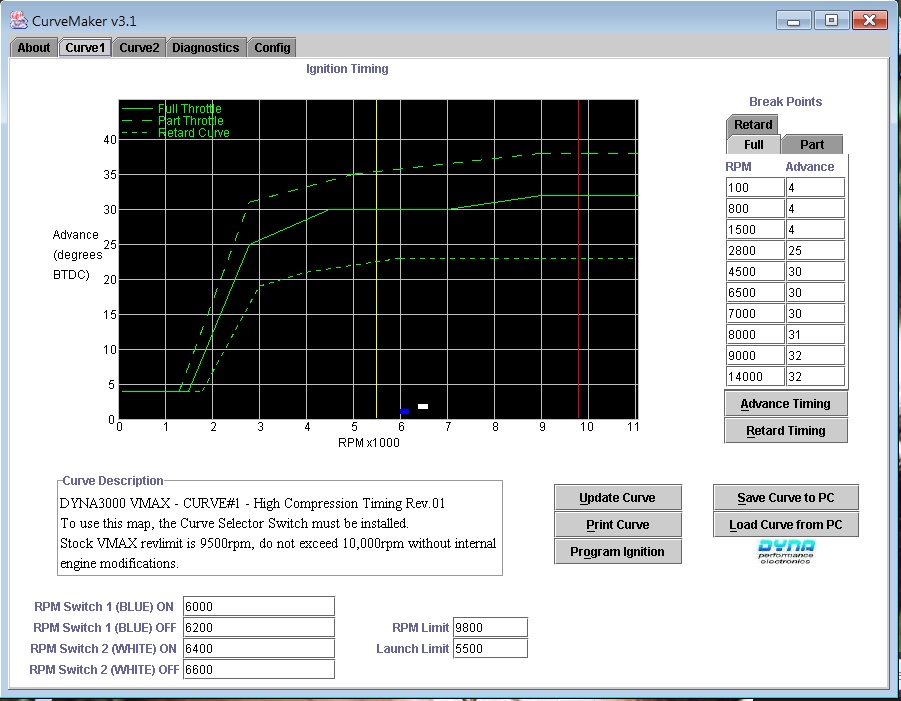

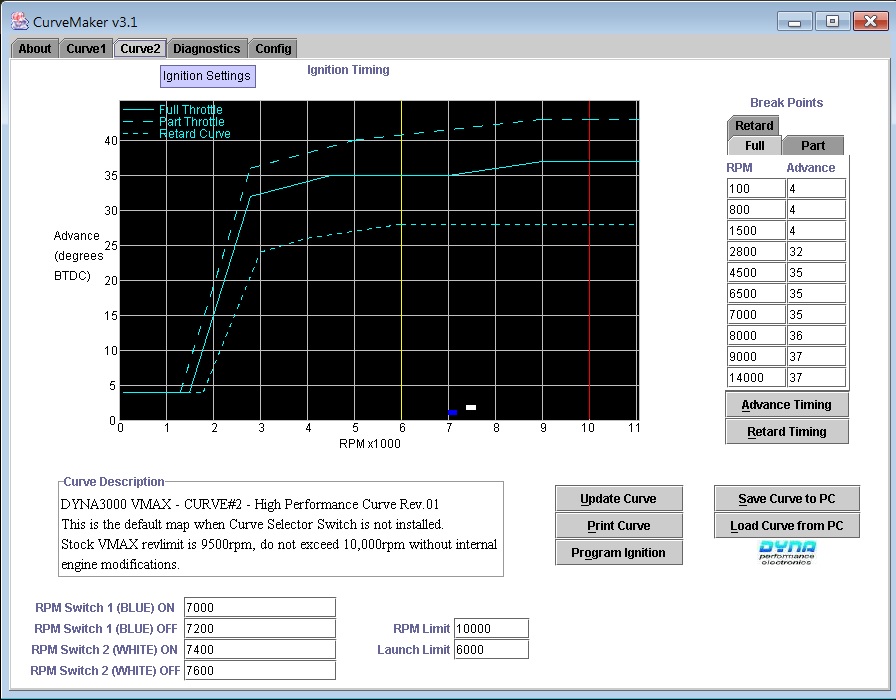

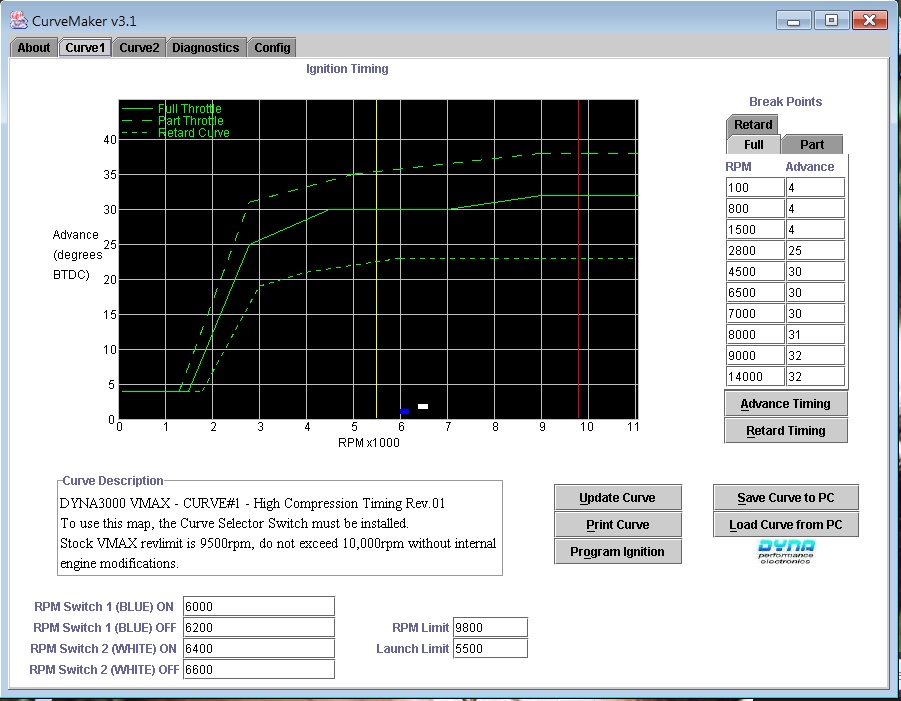

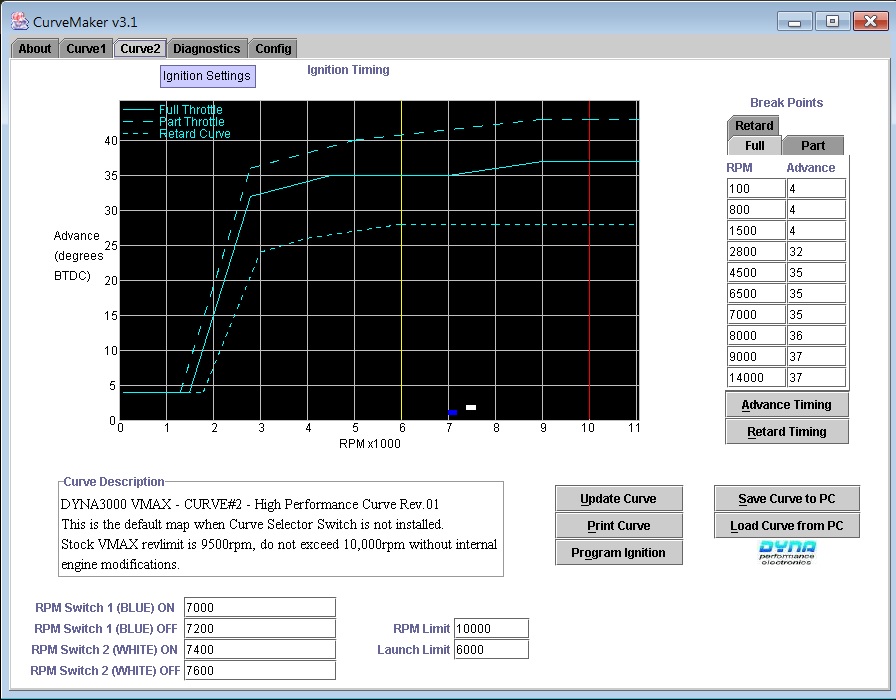

Well I have a copy of the dyna curves.....so just transferred them to the ignitech. The curve #2 added some ponies....almost 2 hp. #3 cost some hp....but then again I only had 87 octane in the tank....so maybe some higher octane gas...I dont know.

thor_eyerdhal

Well-Known Member

Yes but is this copies of the old non programmable Dyna or of the new programmable one?

Traumahawk

Well-Known Member

The older Dyna 3000 curves.

Last edited:

thor_eyerdhal

Well-Known Member

Ok, so you should try the new one, there is a "conservative curve" for high CR and a "performance one" for standard CR that seems to be optimised regarding old ones.

Traumahawk

Well-Known Member

Ok...thanks....i will have to try these.

thor_eyerdhal

Well-Known Member

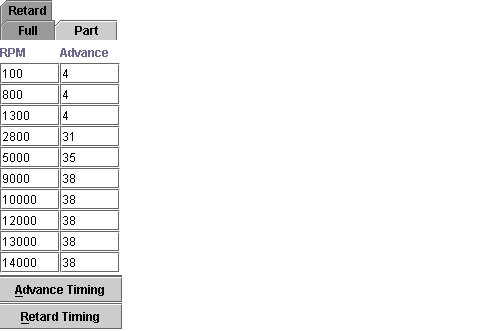

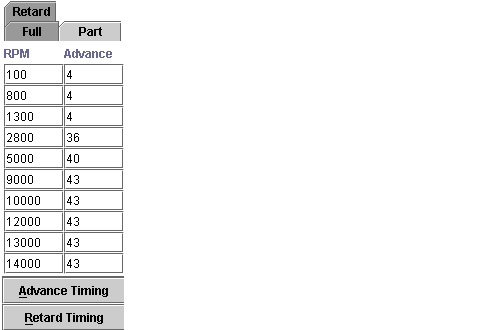

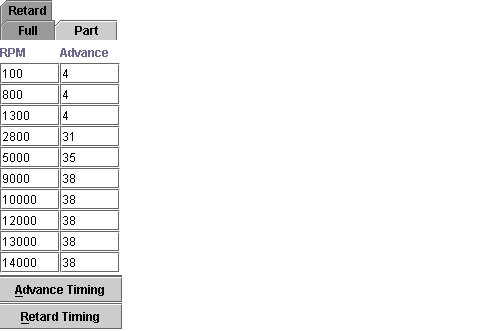

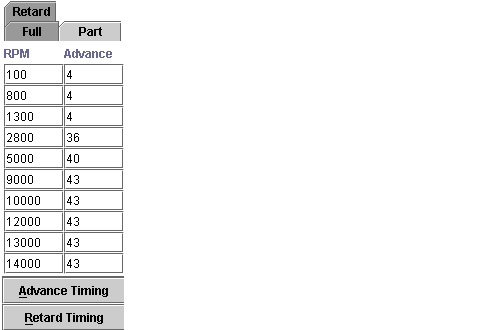

Timing board with vacuum for high CR curve:

Timing board with vacuum for stock CR curve :

Timing board with vacuum for stock CR curve :

veebooster

Well-Known Member

Procedure I use to with MAP sensor set TPS sensor settings. Similar procedure to set IAP stting also.

With PC hooked & and connected to TCI, start motor (warmed up already) choke off.

On the Miscellaneous tab. verify sensor setting is on TPS.

At bottom left of TCIP4 window, there is an RPM =_ and a TP=(%) bar graph. With the motor idling I set the TP graph so the black bar is just at the far right side of block. This is adjusted by changing TPS Voltage setting, the lower green block controls idle setting when using MAP sensor. then programming TCI and rechecking setting. This will take a number of adjustments to get bar to show far right. To set the WOT on left side of bar. I crack throttle wide open and watch screen to see if black bar disappears. The upper green block controls WOT setting when using MAP sensor. Adjust voltage to correct as needed.

If either setting is to the far left or far right of graph, the voltage settings need to be adjusted to bring bar back on graph so as to have a point of reference, then adjusted to back just off graph again.

Remember to reprogram after each adjustment.

Due to the sensitivity the TCIP4 software has, the TP setting will pulse, this is normal and happen on all motors.

Gary

Gary, I'm finally playing with my V80 version. I only have the TPS on this one but the voltage readings I'm getting are a lot lower than what you guys are seeing. Max is 1.999 lowest under 1. Is this due to a different MAP?

Thanks, Dale

dingy

Well-Known Member

Gary, I'm finally playing with my V80 version. I only have the TPS on this one but the voltage readings I'm getting are a lot lower than what you guys are seeing. Max is 1.999 lowest under 1. Is this due to a different MAP?

Thanks, Dale

The TPS will result in a different MAP file, though the lower readings are due to differences in the way a MAP sensor works compared to a throttle position sensor (TPS). The TPS is no more than a variable resistor (actually a potentiometer) hooked to the throttle system somewhere, as throttle is opened a variable resistance alters the output voltage. A MAP sensor is an electronic circuit that is similar to a differential pressure sensor. It changes output voltage electronically not mechanically. Voltage readings will be dependent on the value of the variable resistor in the TPS. Lower is not bad, as long as you have a defined closed & wide open throttle setting. The wider the spread between the high & low value will give the best sensitivity for TPS. That's the reason I supply a 1 bar MAP with TCI's I supply. The 1 bar sensor gives about a 1 volt swing, while a more readily available 3 bar sensor would only give about 3 tenths of a volt swing.

The TPS setting is much easier to calibrate.

With PC hooked & and connected to TCI, turn key on. Motor doesn't have to be running for this.

Click on Read icon, this will download what is in TCI to TCIP4 software.

On the Miscellaneous tab. verify sensor setting is on TPS.

There are two blocks just to the left of the 4 green blocks where voltages are set. Upper is Set TPS 0% and lower is Set TPS 100%

With the throttle fully closed, click on Set TPS 0%. Twist throttle to full open and click on Set TPS 100%.

Click on Program icon to load changes back into TCI.

You're done.

My thought is that a MAP (vacuum) sensor is a better indicator of load on a motor than a TPS is, just an opinion though.

Gary

Last edited:

veebooster

Well-Known Member

Will do...thanks for the quick reply Gary. I'll let you know how she turns out. It is running pretty good as is though!

Dale

Dale

Anybody know if there is a replacement MAP Sensor that can be sourced locally? I mean from a general parts store like O'Reilly or NAPA. I was doing a little tweaking with the ignitech and noticed that the MAP sensor was reading 107mV with the engine on or off and did not respond to throttle input. Checked out all of the wiring and it all looks good. Have 5V at the MAP sensor plug. Any suggestions?

Traumahawk

Well-Known Member

I bought a replacement from oreillys here a while back. On the map sensor with the kit it has a GM part number (which references a 90s corvette).