A while ago, before I pulled my carbs apart, I posted a question. In the end I got some 147.5 mains.

I'm doing some carby work now, and it's a little different from what I previously guessed.

My '85 has had the 2 150's changed to 152.5's already. (So it has 152.5's in it.) I guess the rest is stock. (it's a 49 state)

It has a std exhaust with the middle opened up. (Big hole thru the guts, not the holes in the end cap.) I've just added t-boost.

Problem was, it was running rich. A friend told me when I gave it WOT from the traffic lights it would blow black smoke as the revs built up a bit. Actually he said he had to dodge the black shit shooting out the back... oops.

Now that I have it apart, I can see several holes in two of the diaphrams, and all 4 diaphrams are see through around the edge where the metal lip sits.

I have repaired the diaphrams and they look OK now. My guess is that holey diaphrams would make it rich.

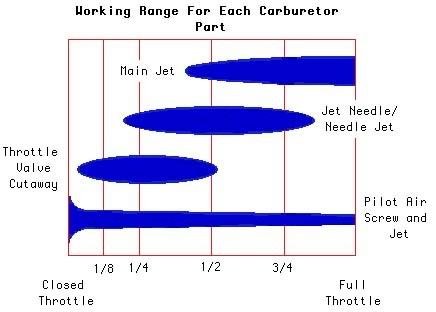

My question is, do you think I should put it back together with 147.5's in it? The only other jets I have are the 152.5's.

If I put the smaller jets, and it seems too lean, can shim the needles?

Baz :biglaugh:

I'm doing some carby work now, and it's a little different from what I previously guessed.

My '85 has had the 2 150's changed to 152.5's already. (So it has 152.5's in it.) I guess the rest is stock. (it's a 49 state)

It has a std exhaust with the middle opened up. (Big hole thru the guts, not the holes in the end cap.) I've just added t-boost.

Problem was, it was running rich. A friend told me when I gave it WOT from the traffic lights it would blow black smoke as the revs built up a bit. Actually he said he had to dodge the black shit shooting out the back... oops.

Now that I have it apart, I can see several holes in two of the diaphrams, and all 4 diaphrams are see through around the edge where the metal lip sits.

I have repaired the diaphrams and they look OK now. My guess is that holey diaphrams would make it rich.

My question is, do you think I should put it back together with 147.5's in it? The only other jets I have are the 152.5's.

If I put the smaller jets, and it seems too lean, can shim the needles?

Baz :biglaugh: