I would never cut a hardened shaft and resplice it unless I knew 100% what the base metal was. I looked into this before along time ago when I wanted to put on the XS750/850 Final drive (2.9) to the XS11 (3.3) for better driveability....Long story short, I discovered a method of shimming the stronger XS11 shaft aft towards the XS750 pinion coupler splines of the FD (mated to XS11 swingarm) and had a simple bolt on FD without comprimising the shaft.....

Anyways don't cut on a shaft unless you are a metalurgist or don't mind fixing the shaft over and over.....

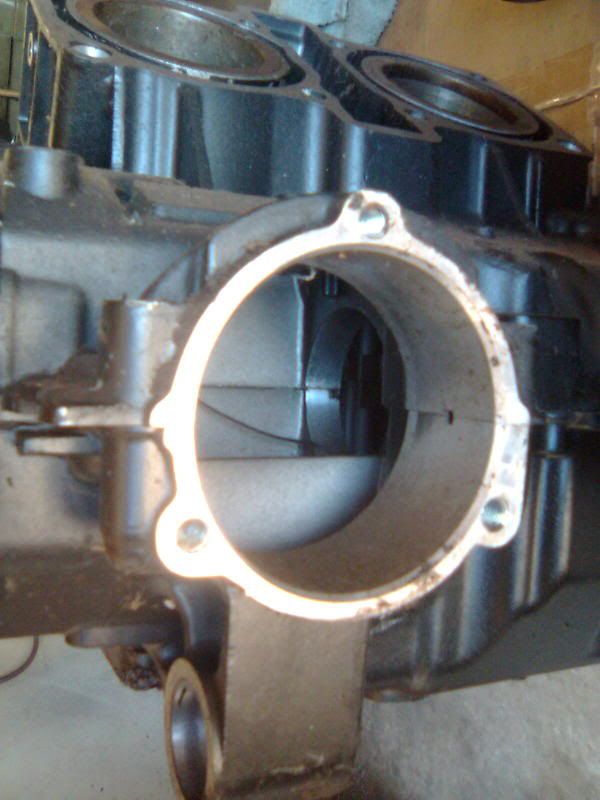

The bevel gear has to go no matter what to install a 1-off custom sprocket adapter over those splines....judging by the stock bevel gear design, a strong enough piece can be machined and case hardened to go right throgh the stock outer bearing I.D. and over the middle drive shaft O.D. once that bevel gear is history...

I can even cryotreat the part. I do this to all my expensive cutting tools and they last 3-4 times as long.

Anyways don't cut on a shaft unless you are a metalurgist or don't mind fixing the shaft over and over.....

The bevel gear has to go no matter what to install a 1-off custom sprocket adapter over those splines....judging by the stock bevel gear design, a strong enough piece can be machined and case hardened to go right throgh the stock outer bearing I.D. and over the middle drive shaft O.D. once that bevel gear is history...

I can even cryotreat the part. I do this to all my expensive cutting tools and they last 3-4 times as long.