Lotsokids

Well-Known Member

1. Cover that intake. It's easy to drop hardware into the carbs with the cover off.

2. Hoist that beast up by the frame.

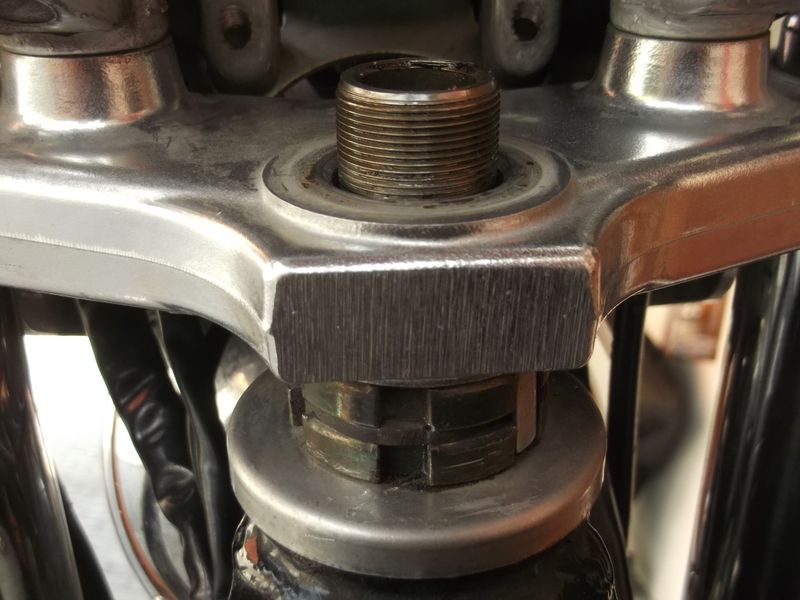

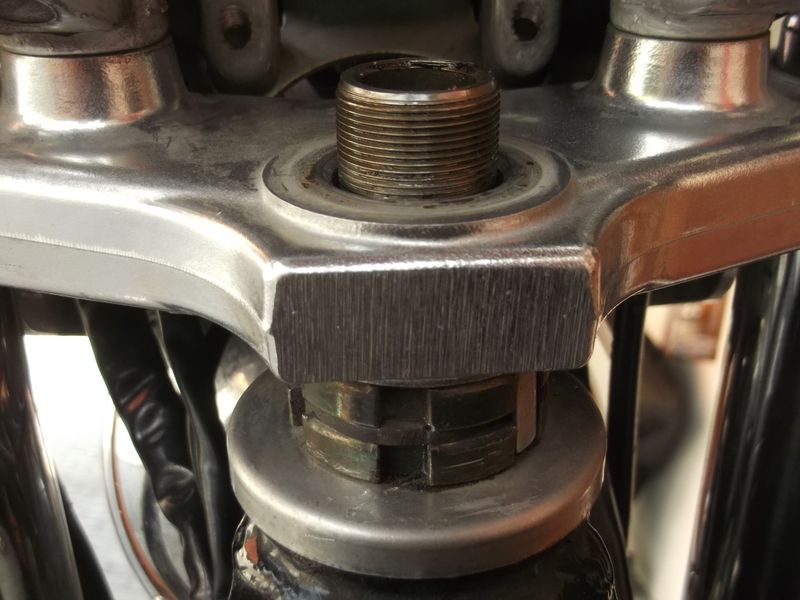

3. Remove the upper retaining nut

4. Chock the front wheel so it doesn't get away from you when you remove the adjusting nuts. Now is a good time to remove the front calipers and speedometer cable at the wheel.

5. Remove the upper brace (this pic is actually the installation - notice the new race).

6. Remove the adjustment nuts and carefully slide the shaft out. I did this by ratcheting my support strap, hoisting the frame up and off the steering shaft with the front wheel chock in plcae. Go slow! Watch the wires and cables!

7. Now you have a "headless" V-Max. :biglaugh:

8. Of course, it's not real maintenance without blood. :confused2:

9. The old lower race. Notice the scars.

10. The only thing I had to remove the bearing races was an old 1/2-drive extension that I've used as a punch for about 30 years.

Notice the end is flared. I used a grinder to form it a little better. That's the only thing that could catch the inner lip to drive the race out.

11. Removing the old lower bearing.

12. Installing the new lower bearing. Be careful to only drive it on at the inner part of the bearing. Some use a pipe or other things, but this is all I had.

Make sure you pack the new bearings well with with grease.

13. Install everything back together, and properly torque the head or use Sean Morley's "bounce" method, which I used.

Note: If you hoist the frame like I did with a similar ratcheting strap, when lowering - get a couple people to help support the bike. Then jack the bottom of the bike up with a hydraulic jack. With the bike supported by your helpers, release the strap ratchet, then lower the bike down to the ground with the hydraulic jack. It's tricky, but works. I actually did this alone, but that's very risky.

2. Hoist that beast up by the frame.

3. Remove the upper retaining nut

4. Chock the front wheel so it doesn't get away from you when you remove the adjusting nuts. Now is a good time to remove the front calipers and speedometer cable at the wheel.

5. Remove the upper brace (this pic is actually the installation - notice the new race).

6. Remove the adjustment nuts and carefully slide the shaft out. I did this by ratcheting my support strap, hoisting the frame up and off the steering shaft with the front wheel chock in plcae. Go slow! Watch the wires and cables!

7. Now you have a "headless" V-Max. :biglaugh:

8. Of course, it's not real maintenance without blood. :confused2:

9. The old lower race. Notice the scars.

10. The only thing I had to remove the bearing races was an old 1/2-drive extension that I've used as a punch for about 30 years.

Notice the end is flared. I used a grinder to form it a little better. That's the only thing that could catch the inner lip to drive the race out.

11. Removing the old lower bearing.

12. Installing the new lower bearing. Be careful to only drive it on at the inner part of the bearing. Some use a pipe or other things, but this is all I had.

Make sure you pack the new bearings well with with grease.

13. Install everything back together, and properly torque the head or use Sean Morley's "bounce" method, which I used.

Note: If you hoist the frame like I did with a similar ratcheting strap, when lowering - get a couple people to help support the bike. Then jack the bottom of the bike up with a hydraulic jack. With the bike supported by your helpers, release the strap ratchet, then lower the bike down to the ground with the hydraulic jack. It's tricky, but works. I actually did this alone, but that's very risky.

Last edited: